Technical Specifications and Details

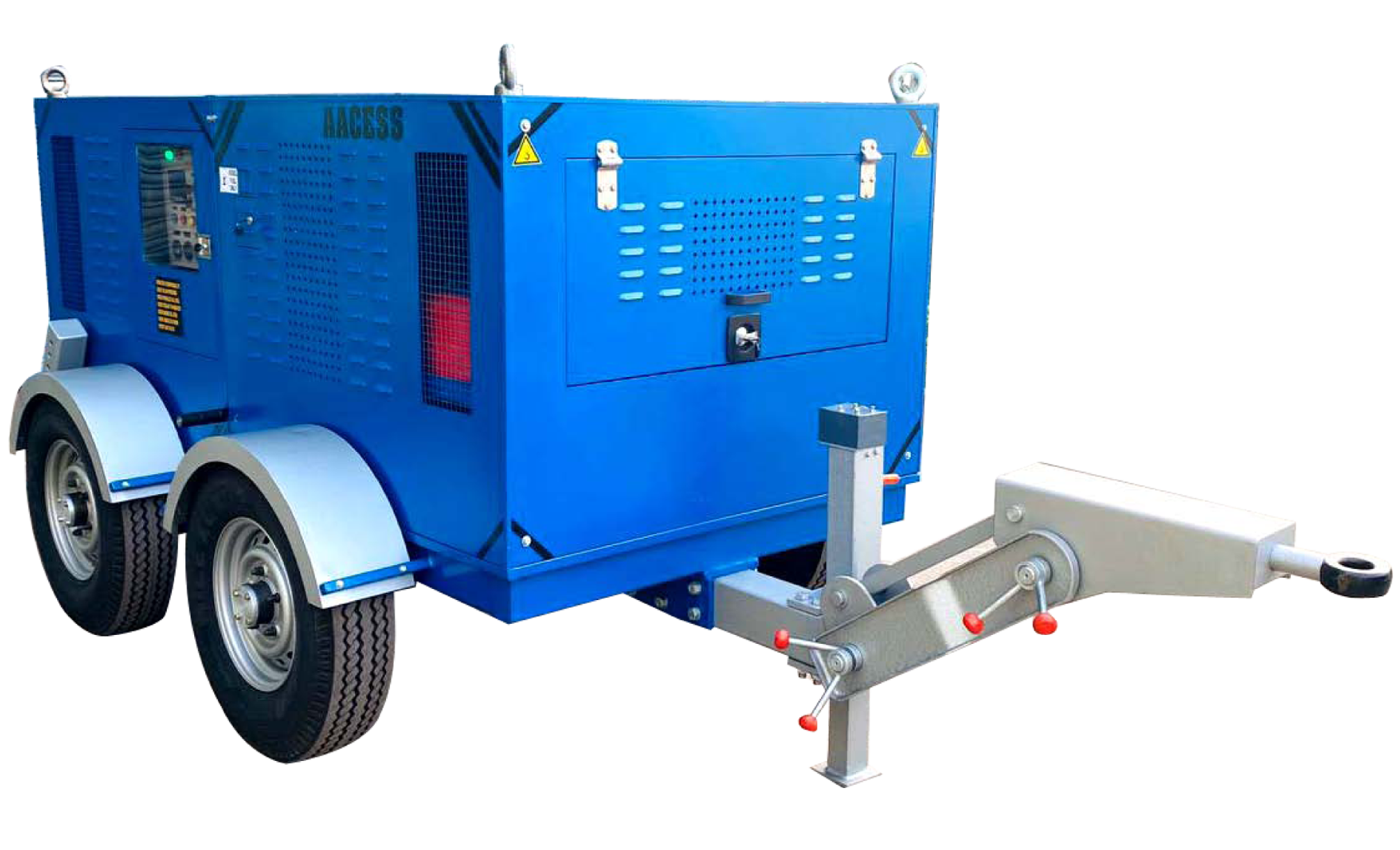

The Unit is called as a Cable Pulling capstan Winch – Hydraulically Operated to be primarily used for underground cable pulling the unit has a pulling capacity of 15 Tons and is designed to pull a length of 1000mts. It is powered by a turbo Charged diesel Engine.

Basic Working Principle of the Equipment

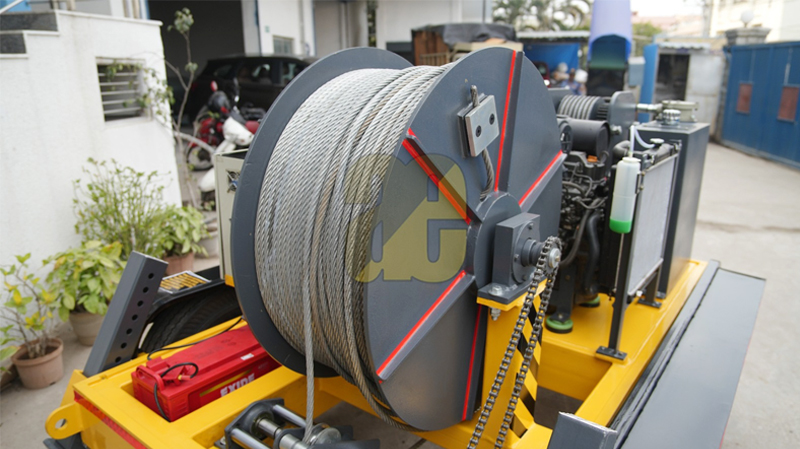

A cable pulling capstan winch which has a rope drum having designated length and diameter wire rope on it and this rope is taken out through double capstan unit and is guided out to the target through pulleys. This unit is powered by diesel engine which drives a closed loop hydraulic pump, which in turns develops oil pressure and supplies this oil to the hydro motor which drive the double capstan via a Gear box there by pulling wire rope.

Download Brochure

Performance Details

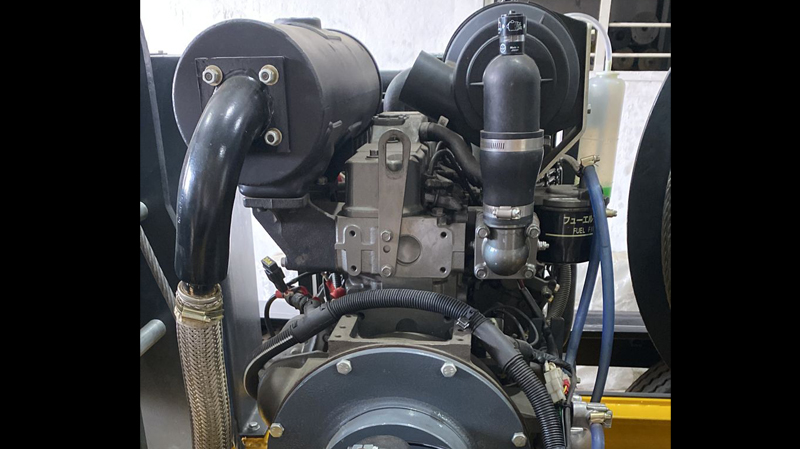

Engine

Yanmar - JAPAN

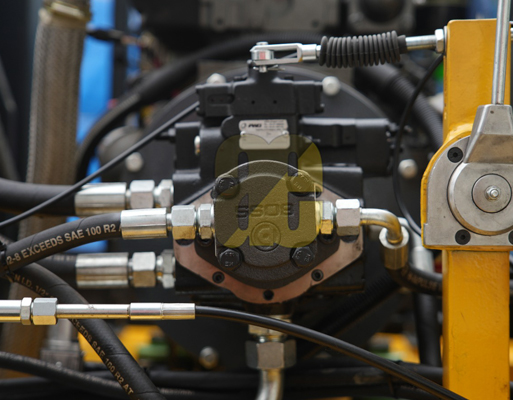

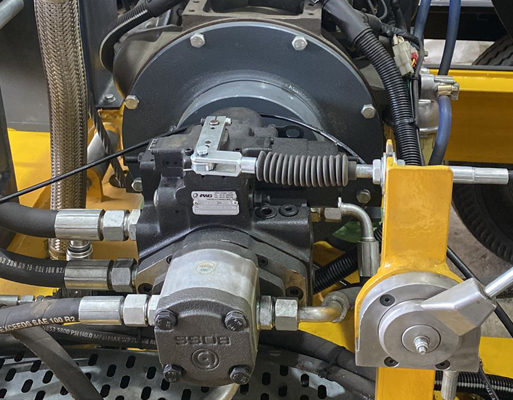

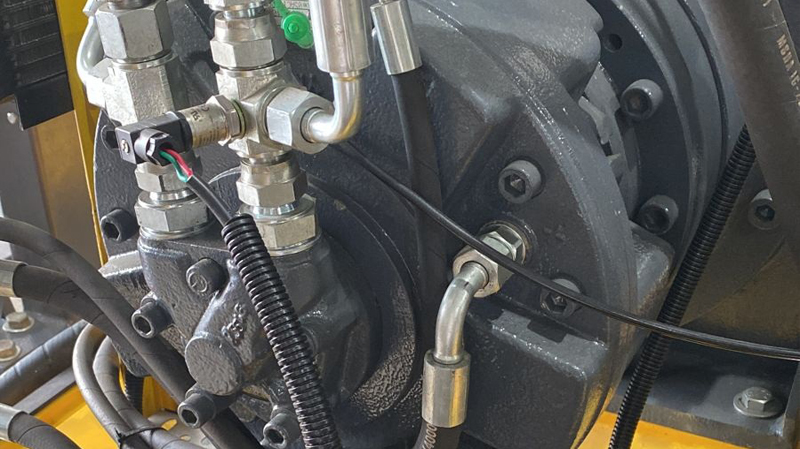

Hydraulic Pump

Bondioli Pavesi / Kolben -ITALY

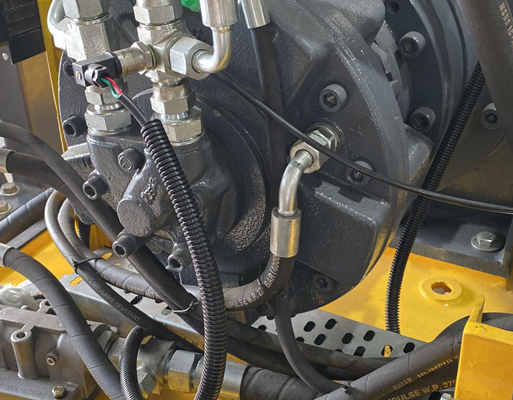

Hydraulic Motor

SAI - ITALY

Rope Drum

Galvanised Wire Rope - Usha Martin with 12mm Dia

Triple Stage Capstan

AACESS

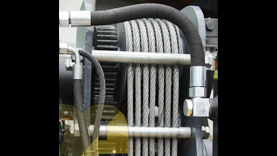

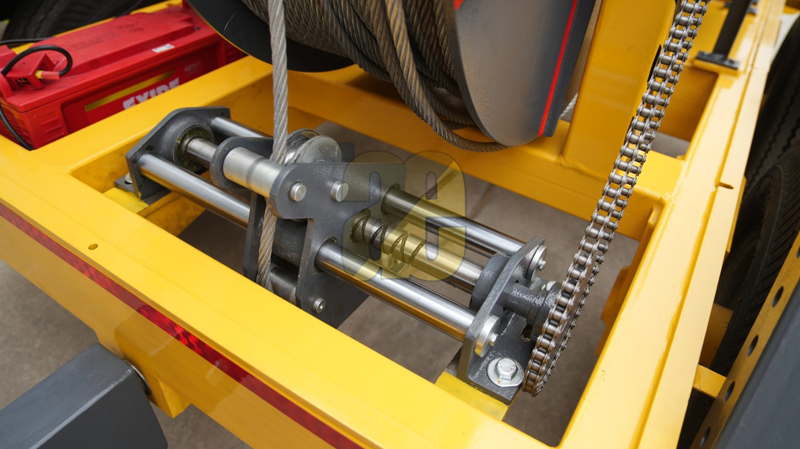

Screw Rod

Diamond Screw Self Adjusting - AACESS

Control Panel

PLC/ HMI - Siemens with Printer

Pulling Structure

Height Adjustable

Operational Features

- Hand operated servo Control System for varying the Speed during pay In and pay Out.

- Continues Display of the Length of the Cable being Pulled.

- Facility to record the name of the Project, cable details and Cable Size.

- Facility to take a print out of the load and speed of pulling as per your convenience.

- Ease of Setting the cut off load in Kgs and speed value in Mts/min using a user friendly human Machine interface Unit.

- User Friendly control panel with all functions like reset, Emergency stop, Engine Start & Stop and Engine performance details displayed.

Broad Technical Specifications

Dimensions of the unit

4100mm(L) x 2100mm(W) x 1750mm(H)

Type of power source engine

Three Cylinder Turbo Charged Diesel

Power Of Diesel Engine

69HP at 1500 RPM

Maximum Speed on Full Load

18 mts / min

Type of Cooling

Water Cooled

Rated Fuel Consumption

10lit / hr at 1500RPM

Min Fuel Consumption

5lit / hr at 1500RPM

Electrical Control Voltage

12V

Method Of Cooling

Sp. Heat Exchanger Provided

No of Wheels Provided

4 No's

Canopy For The Total Unit

provided

Rope Guide Unit For Drum

provided

Working Pressure Of Hydraulic

Max 225 Bar

Coolig System

Hydraulic Oil Cooler

Capstan Diameter

300ms

Types of Capstan

Double

Safety Devices Incorporated

- The unit is totally covered for safety purpose.

- The reset button must be operated as per the procedure.

- Two sets of jacks anchor between the rope drum and the output guide.

- Guiding rollers provided in front of the pulling line to avoid higher angular pull.

- Auto cut off the Hydraulic unit when the speed of the wire rope exceeds the set speed on the HMI.

- Control panel features an emergency stop button and hydraulic circuit bypass for line pull release in emergencies.